About

Technology

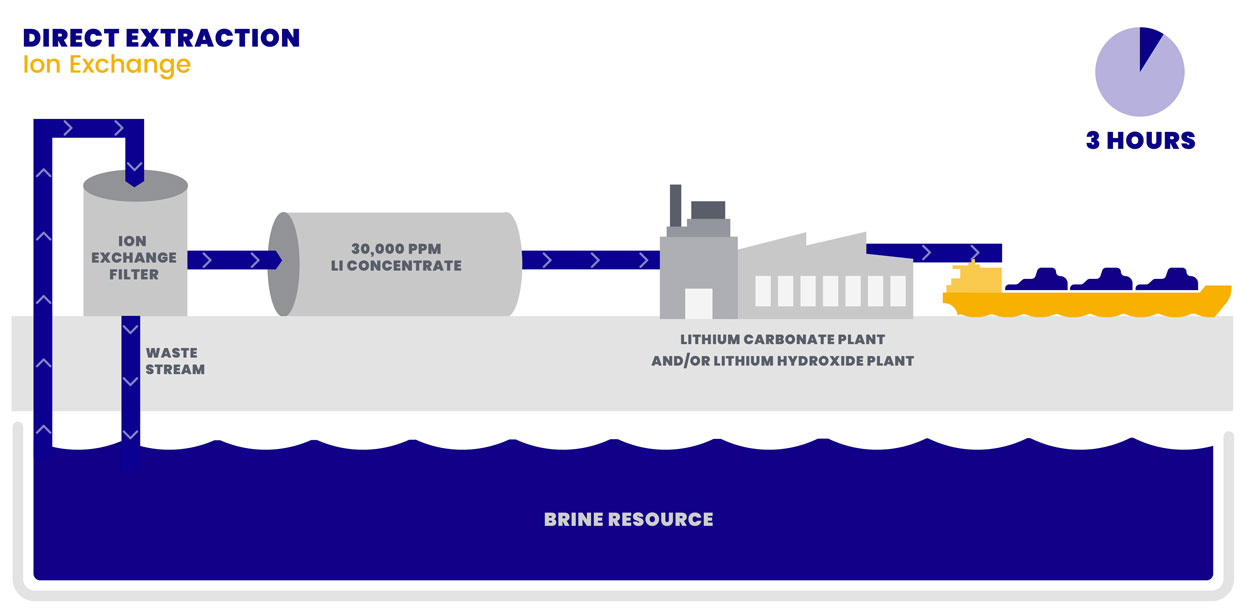

Lake Resources is demonstrating the use of clean technology together with our technology partner, Lilac Solutions. This direct extraction process uses an adaptation of ion exchange technology, used widely since the 1940’s in water treatment, to reduce lithium processing costs and timelines significantly.

Conventional lithium extraction from brines involves salt-rich waters under salt lakes being pumped to the surface into large ponds, where solar evaporation reduces the liquid content. Typically, this process can take between nine months and two years and with lithium recoveries usually below 50%.

In contrast, the innovative solution developed by California-based Lilac Solutions offers a fast-track production process, with lithium brines produced in under three hours with very high purity and with minimal environmental impact.

Lab testing has shown that lithium concentrations of 30-60,000 mg/L lithium can be produced from brines of ~300 mg/L lithium in a few hours using the Lilac process.

Lilac’s unique ion exchange beads and column system together enable a simple and robust process yielding concentrated high-purity lithium solutions.

Testing undertaken in January 2020 confirmed very high purity lithium carbonate with 99.9% purity could be produced using Lilac’s technology. This exceeded industry standard specifications for battery-grade purity (more than 99.5%). A significant outcome was that very low impurities were produced, with results of iron (Fe) and boron below 0.001 wt% (weight percentage).

Major Milestones Achieved in Kachi Demonstration Plant using Lilac DLE Technology

- DLE demonstration plant continuously operational for more than 2,500 hours with 90% uptime

- Lithium Carbonate exceeds battery grade requirements > 99.8% purity

- Highly selective process with consistent results on sample testing

- > 90% impurity removal

- > 80%1 lithium recovery

- Produced 120,000 litres of eluate containing more than 2,500kg of LCE

- Initial offtake samples shipped

- Lithium carbonate demonstration plant currently producing

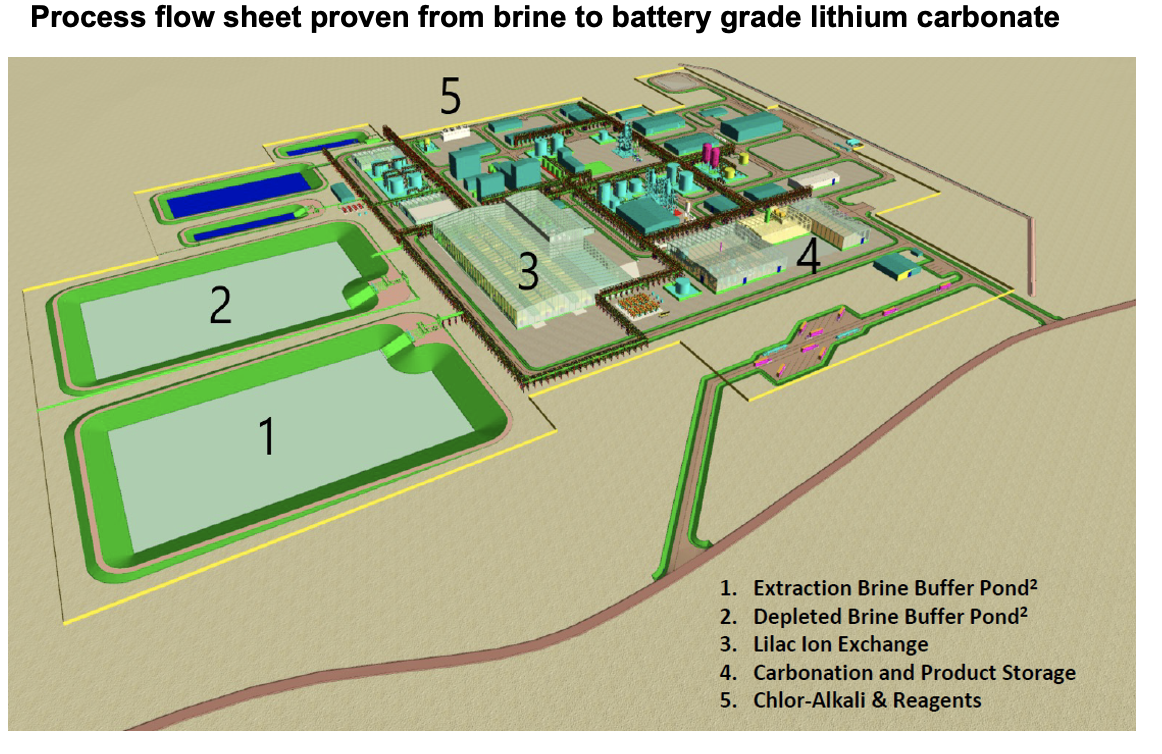

On 17 April 2023, Lake and Lilac announced the production of 2,500kg of lithium carbonate equivalents (LCE) at Kachi. Based on this successful result, Lilac increased its ownership of the Kachi Project from 10% to 20%. The project is now on track to move from its pilot phase into commercial-scale development, which will make it the first lithium brine project in South America to produce lithium at commercial scale without the use of evaporation ponds for lithium concentration.

The achievement at the Kachi Project represents a historic advancement in lithium production technology. This is the first successful implementation of ion exchange for lithium production in South America, home to most of the world’s lithium brine resources.

The 2,500 kg of LCEs was extracted at Kachi with 80% lithium recovery, 90% plant uptime, 1,000x less land compared with evaporation ponds, and 10x less water compared with conventional aluminum-based absorbents. The results speak for themselves:

• Speed to Production: Lake and Lilac commissioned the plant on-site in under a month, more than 10x faster than conventional processes, and immediately began continuous production of lithium chloride;

• High Lithium Recoveries: Lake and Lilac are achieving 80% lithium recovery from a brine with 200-300 mg/L of lithium, roughly double the lithium recoveries of most brine production despite having a lithium grade 2x-7x lower;

• High Water Efficiency: This technology is extremely water efficient, enabling production of lithium chloride with 10x less water compared to conventional aluminum-based absorbents;

• Product Purity: The lithium chloride being produced is low in impurities, enabling efficient production of high-purity lithium carbonate for battery manufacturers. Rejection of boron, a troublesome impurity for brine projects, is greater than 99.9%;

• Continuous Operations: The plant has been operating 24/7, with 90% uptime; this is a reliable automated plant designed for scalable manufacturing and operations;

• No Evaporation Ponds: Lilac’s ion exchange technology does not require evaporation ponds for brine concentration, unlike other so-called “direct extraction” technologies which rely on evaporation ponds to concentrate the lithium;

• Validated Performance: An independent engineer has visited the plant and analysed more than 100 samples from across the plant to validate performance and confirm consistency with engineering work.

When fully developed by Lake and Lilac, the Kachi project is expected to produce 50,000 tonnes per annum of battery-grade lithium products.

Notes:

1. For DLE recovery only; >76% for total plant

2. Buffer pond size for our target 50Ktpa plant capacity is more than 100x smaller than evaporation ponds required for same output.